What are LED Light Pipes?

What is a LED Light Pipe?

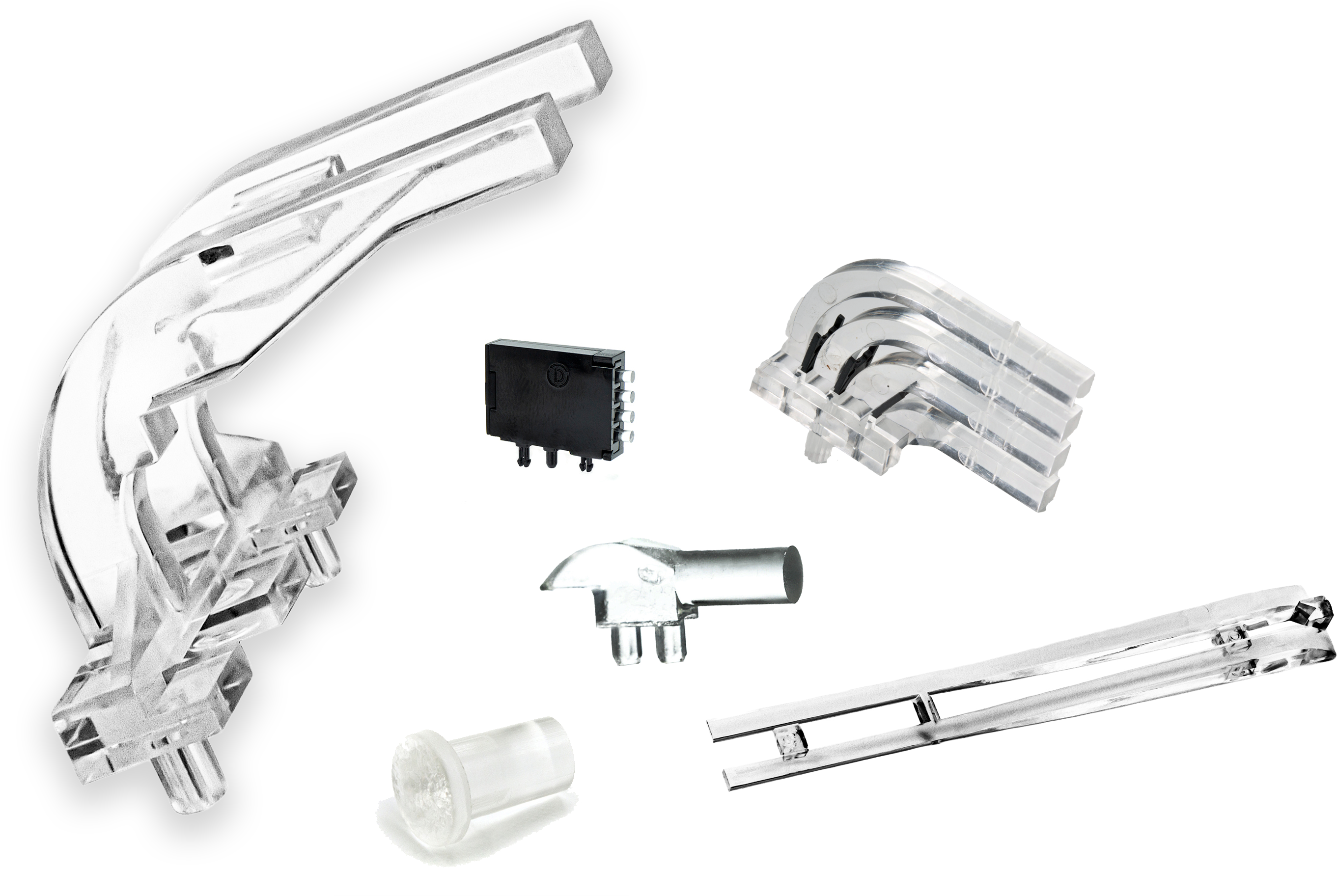

A LED light pipe is an engineered, precision molded optical component or optical fiber that transmits light from the light source, i.e. LED on a circuit board, to the outside of the housing or panel. They are typically produced from Polycarbonate or other optical grade material. To ensure high performance and durability, Dialight only uses fresh, high-quality polycarbonate in the production of its Optopipe® light pipes; never reused polycarbonate material!

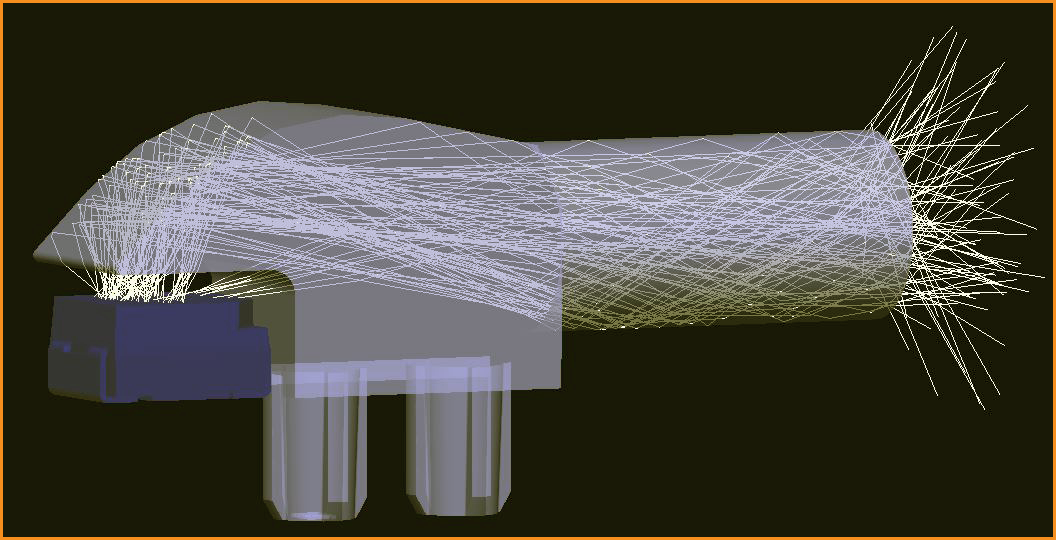

Cutting edge light pipe design and development empowerd by ray tracing technology.

At Dialight, ray tracing is used to analyze the path the light takes through the light pipe. This modeling method is employed prior to actual production to ensure the maximum performance of light pipe designs by minimizing the light loss.

Why use a LED Light Pipe?

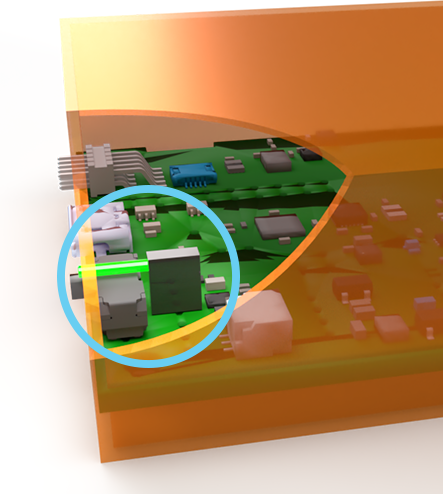

Optopipe® light pipes are used for visual status indication and provide for safe and reliable operation of electrical equipment, instruments, electronic devices, and serve diagnostic purposes as well.

They are typically used for front-panel indication when traditional indicators are too large or other space constraints exist. Sometimes indication is required over, around, or beneath front-panel components, such as ports or switches, and light pipes provide the solution to this frequently encountered problem.

They can also be utilized when EMI/RFI concerns require the light source to be away from the front panel, or when indication needs arise after the mechanical design is completed.

Optopipe® light pipes eliminate the need for costly PCB or panel layout redesigns and are generally more cost-efficient than alternative indicator technologies.

There are a vast number of configurations and features available to the end-user to achieve the desired visual status indication needs for most applications.

Mounting Options for LED Light Pipes

Optopipe® light pipes are either PCB mounted or panel mounted. Light pipes designed for PCB applications have mounting pins and can be easily installed by pressing into holes drilled into the PCB.

The mounting of an Optopipe® Light Pipe on a PCB requires an interference fit to maintain the integrity of the connection between the light pipe and the circuit board. The circuit board mounting hole is typically a few thousandths (0.00x) smaller than the overall diameter of the light pipe mounting pin's outer dimensions but larger than the solid core of the mounting pin. The outer diameter of the mounting pin is defined by the outer dimension of the crush pin details. As the light pipe is inserted, these crush pin details deform slightly, creating a snug fit between the light pipe and the circuit board. Most light pipes feature a flat stop detail where the pin connects to the light pipe. For consistent performance, this flat surface should be seated on the circuit board surface.

When mounting the light pipe, even pressure must be applied uniformly across multiple mounting pins due to the interference fit. Any misalignment between pins can create unbalanced pressure, making installation difficult. A mounting tool facilitates this process by ensuring even insertion. The proper design of the mounting tool includes pins that match the number and placement of the light pipe's mounting pins. These tool pins must be centered over the light pipe's mounting pins to distribute force evenly. Additionally, the tool must have a cavity taller than the highest point of the light pipe to prevent damage to the optical surface.

This insertion technique, particularly for multi-element light pipes, is widely used across the industry and has been employed internally at Dialight when testing various crush pin designs.

For panel mounts, they are pressed into the front panel and rest on the PCB, just above the LED(s). If the given application requires additional support, Epoxy gluing or heat-staking is recommended.

Positions and Directions of LED Light Pipes

Optopipe® light pipes are available in single and multiple position configurations and typically feature 1 to 4 indicator positions in either horizontal or vertical directions. There are straight, right-angle, and stacked options to accommodate various application requirements.

Single position light pipe

Multiple position light pipe

Right-Angle light pipe

Vertical light pipe

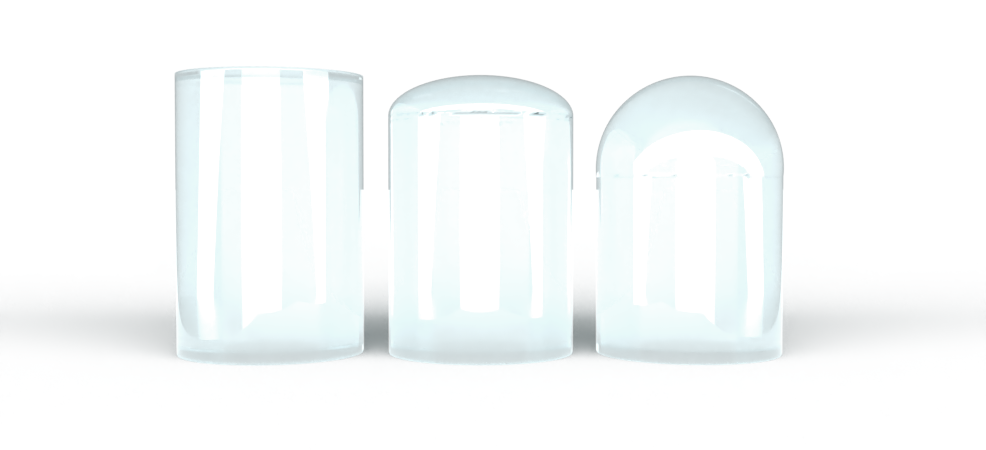

LED Light Pipe Lens Types

Round - Square - Rectangular

Flat - Convex - Domed

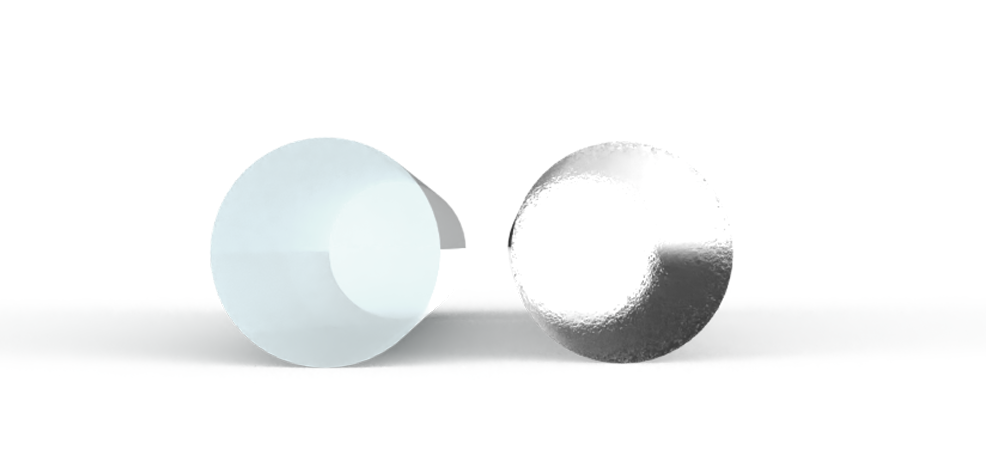

Polished - Textured

There are several available lens options depending on the application needs or desired panel looks such as protruding or flush mount lenses, viewing angles, direct view or back lighting needs. The basic lens shapes are round, square, and rectangular. The available lens tip configurations are flat, convex, or domed. Additionally, lenses can be either polished or textured.

Light Pipe Shielding Options

Shielded - 515-1064-804F Optopipe® Light Pipe

Unshielded - 515-1064F Optopipe® Light Pipe

Optopipe® light pipes are available in Shielded and Unshielded configurations.

Shielding optimizes the light output of the light pipe by preventing light bleed and eliminating optical crosstalk between adjacent light sources.

Other variables that affect the light output of the light pipe are the type of LED used with the light pipe and the distance between the LED and the light pipe. Therefore, Dialight generally recommends a specific LED for use with a given Optopipe® light pipe.

Optopipe® Light Pipe Advantages

Design Flexibility

○ LED light pipes are available in numerous configurations and styles to accommodate even the most challenging indication needs.

○ They are easy to install on a PCB or in a panel.

○ Light pipes can be used with surface mount or through hole LEDs. *Dialight generally recommends a specific LED for use with a given light pipe.

○ They offer a degree of customization. Configurable Height & Length light pipes and vertical light pipes offer the most customization options for height and lenght dimensions.

Cost Savings

○ Light Pipes are generally more cost-efficient than alternative indicator technologies.

○ They eliminate the need for costly PCB or panel layout redesigns.

Performance

○ Light Pipes provide unvarying indicator illumination across different heights and lengths of the pipe.

○ Shielded light pipes efficiently eliminate light bleed and optical cross-talk.

Optopipe® light pipes are a versatile solution to your front-panel indication needs. They come in a variety of configurations and lens options to meet the specific needs of your application, even after mechanical- and panel design layouts have already been completed.

With Optopipe® light pipes, design engineers get the performance, design flexibility, and cost savings they are looking for; all in one visual status indicator product.